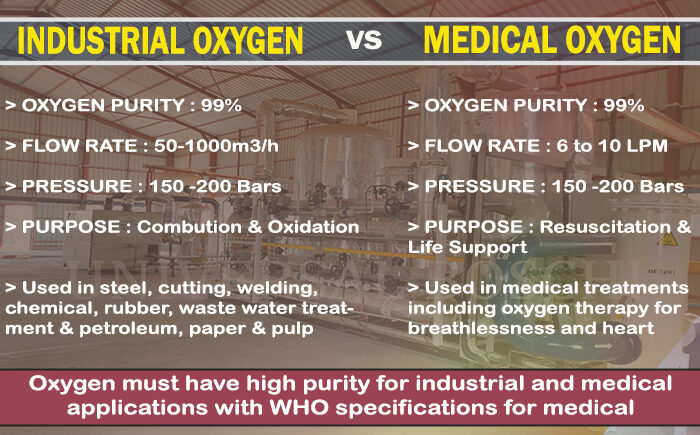

Oxygen is a vital non-metallic element valued for it its reactive properties. All living beings need to breathe it to stay alive. However, it is used for both medical and industrial with different specifications and focus.

Expert bodies issue specific instructions for productions of medical grade oxygen. The US pharmacopeia, the UK Pharmacopeia and Indian Pharmacopeia prescribe strict criteria for generation. The WHO (World Health Organization) has included oxygen as a drug and included it amongst its Essential List of Medicines 2021. The WHO has also updated specifications for PSA oxygen plants for compliance. The following specifications must be fulfilled for medical oxygen:

- Oxygen purity must not be less than 99%ppm

- Carbon dioxide must not exceed 300ppm

- Water content must remain below 67ppm

- Carbon dioxide content must be below 7ppm

Normally, we do not see much of a difference oxygen and medical oxygen. However, it is not so as there is a big difference. We will discuss difference between medical & industrial gas in detail. We will talk about industrial oxygen in the next heading.

Coming back to medical oxygen, it is imperative that we generate oxygen for medical purpose through PSA or cryogenic oxygen plants in compliance with the WHO oxygen specifications. Typically, we prepare high purity oxygen for human respiration and numerous medical treatments. Medical oxygen cylinders thoroughly cleaned to prevent contamination.

The US Food and Drug Administration (FDA) are responsible for regulating medical oxygen since it is a drug. Understandably, the FDA ensures that patients receive the safe and standardized percentage of oxygen. However, different patients might require different amount of oxygen depending upon their condition. It is must for the patients to visit a doctor for prescription.

Moreover, it is also necessary for medical oxygen cylinders to be without any trace of contaminants. There must be a chain of custody to ensure that the cylinder is without any trace of contaminants and has not been used for refilling industrial oxygen. If a cylinder has been used for industrial purposes it cannot be used for medical oxygen.

Industrial oxygen gas is also used for maintaining and industrial functions. Mainly, properties of oxygen such as high reactivity are valued. Moreover, the highly reactive gas also supports combustion. This particular property is very useful in sustaining manufacturing activities in numerous industries including steel, chemical, metal fabrication, medical, paper & pulp, oil & gas, wastewater treatment, etc.

Apart from combustion & oxidation, oxygen is also used as catalyst in chemical reactions. It is no surprise that chemical industry is the 2nd largest consumer of industrial oxygen after the steel industry.

However, it is important to note that industrial oxygen is not appropriate or fit for human for human consumption. There might be contaminants present in industrial oxygen that can potentially make people sick.

Industrial oxygen must have high purity for maintaining industrial processes but there are no strict compliance instructions for purity unlike medical oxygen. Industries can use suitable purity that meets their purposes and requirements.

Some of important specifications are discussed below:

Purity

The industries demand oxygen plants that can generate high purity oxygen but in actual use they might use even lower purity oxygen. Broadly speaking, purity level depends on the needs of industries.

Flow

Flow rate of oxygen depends on the amount of oxygen an industrial process needs. For larger requirements bigger flow rate is needed.

Pressure

Pressure of oxygen cylinders is kept between 150-200 bars. However, the industrial can vary it as per their requirements.