There are many techniques for generating oxygen for meeting the requirements of industrial and medical applications. The most common techniques being cryogenic distillation, pressure swing adsorption and membrane separation.

Pricing of Cryogenic and PSA technology is different

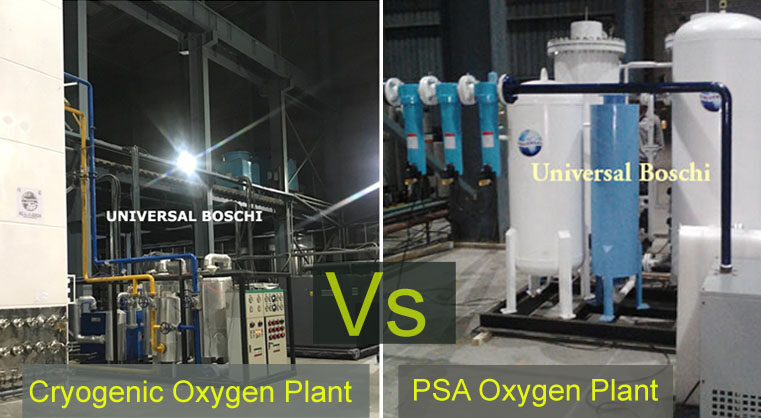

Customers new to the oxygen industry do not understand the difference between cryogenic based oxygen plants and PSA oxygen plants. Mostly, they are of the view that all O2/N2 gas plants are priced like PSA plants which is not true. pressure swing adsorption plant cost does not match with the cryogenic based plants since both the technologies are completely different.

Pressure swing adsorption technology is suitable for businesses requiring oxygen with lower volume and lower level of purity. PSA process runs on simple process of adsorption where adsorbing material such as Zeolite molecular sieves is used with one gas being adsorbed more than the other. When air is passed nitrogen is adsorbed while oxygen is allowed to pass through.

As PSA pressure swing adsorption process is employs simpler technology costs less to manufacture PSA plant price is way less than cryogenic based plants. Cryogenic technology is sophisticated and requires use of elaborate process with components that are way more costly than those used in PSA process.

Oxygen Purity with PSA Vs. Cryogenic Process

As mentioned earlier, PSA is ideal for generating oxygen with lower purity and volume as compared to cryogenic air separation which is used for generating oxygen with the highest possible purity and larger volume.

Tonnage cryogenic plants can produce oxygen on a huge scale with very high purity which is not possible with PSA plants. PSA plants are rarely available with configuration of 200m3/hr not to talk of tonnage plants.

Cryogenic plants can generate both oxygen and nitrogen

PSA plant can generate only one product gas either nitrogen or oxygen. On the other hand, a cryogenic plant can produce both oxygen and nitrogen. If you have an oxygen plant it can also produce nitrogen. However, it would require you to buy a nitrogen cylinder filling system.

Cryogenic process can generate oxygen in liquid and gaseous forms

Cryogenic oxygen plant can generate oxygen in both liquid and gaseous forms. And, psa oxygen generator plant can only produce either oxygen or nitrogen in the gaseous form only.

Different life-cycles

Both cryogenic and PSA plants have got different life-cycles. Where PSA is known to have life cycle of over 10 years cryogenic plants have life cycles of over 25 years. This becomes possible because the cryogenic O2/N2 plants are fabricated with cryogenic grade stainless steel which is capable of withstanding extreme temperature and pressure. Cryogenic air separation units are welded with TIG argon welding.

Applications of PSA oxygen plants

PSA plants are best suited for small industries requiring oxygen with lower volume and where oxygen with lower purity is also acceptable. The plants are best suited for following industries:

Welding /cutting/heating

The plants are ideal for onsite generation of oxygen for use in welding and cutting. In this industry oxygen is used along with acetylene where purity is not an issue.

Blowing of glass and beads

It can also be used in glassware industry for blowing glass and beads. It is a cottage industry where oxygen is needed for making various types of glassware products.

Fish farming

It is another application where small psa plants are used for oxygenating pond water to improve oxygen content in the water which is essential for improving health of fish.

Applications of Cryogenic Oxygen Plants

Cryogenic oxygen plant is suitable for industries that require production of oxygen or nitrogen in larger volume and with high purity. Some of the industries using cryogenic plants are given below:

Steel industry

Steel industry is the largest consumer of commercially produced oxygen. Onsite cryogenic plants are used in the steel industry for generating oxygen in large volumes with high purity

Chemical industry

This industry is the 2nd largest consumer of oxygen after the steel industry. Here also oxygen in larger volumes with higher purity is required which is possible only with cryogenic process.

Medical or health care industry

In the medical industry also oxygen is required with high purity. Cryogenic oxygen plant is used for generating oxygen with very high purity.